Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat:

Warning: Undefined variable $public in /www/wwwroot/yuelinhengtong.hyhdemo.top/wp-content/themes/hyhadmin/header.php on line 313

Warning: Trying to access array offset on value of type null in /www/wwwroot/yuelinhengtong.hyhdemo.top/wp-content/themes/hyhadmin/header.php on line 313

,. Or call

Warning: Undefined variable $public in /www/wwwroot/yuelinhengtong.hyhdemo.top/wp-content/themes/hyhadmin/header.php on line 313

Warning: Trying to access array offset on value of type null in /www/wwwroot/yuelinhengtong.hyhdemo.top/wp-content/themes/hyhadmin/header.php on line 313

directly.

When it comes to false eyelash production, precision and consistency are everything—especially for wholesale buyers and beauty brands. At our factory, we follow a detailed process to ensure every lash is up to professional standards, ready for bulk orders, OEM projects, or private label launches.

The process begins with carefully selecting the raw lash fibers. Under strong lighting, our workers handpick each piece to make sure only soft, smooth, and uniform strands are used. This ensures consistency in every batch—essential for OEM services and long-term supply needs.

Every lash style is crafted with intention. Using detailed design charts and samples, we match each product to specific client needs—whether it’s for a wholesale beauty store looking for natural styles, or a cosmetics brand needing bold looks for their private label range.

Once the lash layout is confirmed, the fibers are trimmed to exact lengths using sharp precision tools. This helps us maintain uniformity in large bulk orders, avoiding any mismatches that could affect client satisfaction.

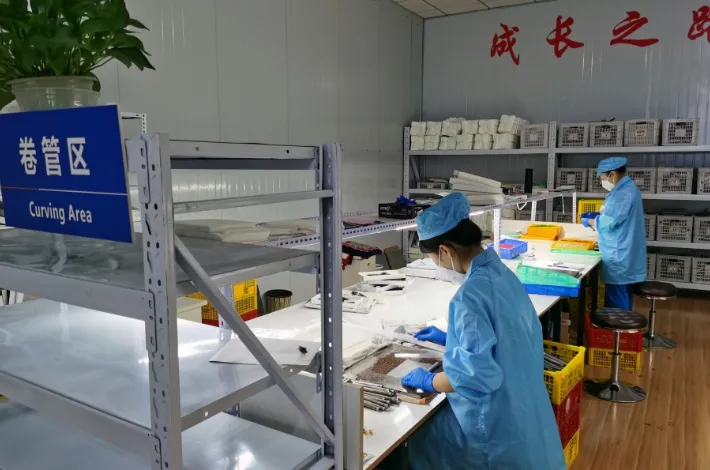

To create the perfect curl—be it a soft C curl or dramatic D curl—we use a heat-controlled curling process. Our technicians monitor temperature and time to ensure every curl is long-lasting and consistent, especially important for OEM services and private label brands with high-quality standards.

The lashes are then placed carefully onto adhesive strips in trays. Each worker checks spacing, alignment, and bonding to ensure comfort and visual appeal. A well-organized process keeps everything neat and helps maintain a stable supply chain, even when demand spikes.

We don’t just check the lashes once—they’re inspected multiple times throughout the process. From length and shape to adhesion and density, every detail is reviewed. Only the best make it into the final packaging, ensuring reliability for wholesale clients worldwide.

Our facility can produce lashes in a huge range of styles—from lightweight and wispy to bold and dramatic. We support full customization in curl, length, and thickness. This flexibility is ideal for both private label programs and OEM clients who want to stand out in competitive markets.

Thanks to our experienced team and structured workflow, we keep operations running smoothly—even during high seasons. This means reliable turnaround times and a strong supply chain to support beauty businesses across the globe.

Despite the careful craftsmanship, our production remains fast and scalable. We’re able to fulfill urgent requests and large bulk orders without delays. Whether you’re launching a new private label line or restocking for wholesale, we deliver with speed and accuracy.

At every step, we focus on helping our B2B clients grow—through trusted OEM services, flexible customization, and efficient delivery. If you’re looking for a reliable lash factory that understands your needs, we’re here to support your success.